|

| Romain Gauthier |

In the last twelve months I have had the immense pleasure of handling a

few of the world's most extraordinary timepieces. These include: Harry Winston's

Opus V, F.P. Journe's Sonnerie Souveraine, the Quentin, MB&F's HM1 and URWERK's

new 201. As a result, it takes a very special timepiece to surprise me.;

however, recently I had a very big surprise from an apparently very simple

watch by someone I had never heard of: a young man called Romain Gauthier.

|

| First photo Shoot. Photographers Marc Amiguet and Martial Fragniere |

A few weeks ago a professional photographer friend gave me a call to say

that he was shooting a watch and invited me to observe how the pros do it.

No doubt he knew I needed all the help I could get, and so did I, so I jumped

at the chance. I asked what the watch was but the brand did not ring any

bells, and anyway, the photographic methods were the main attraction for

me, not the subject.

At first glance it appeared to be a very nicely designed clean dial, beautifully hand guilloched in a quality gold case. Nothing sensational; however, it was obviously extremely well made and well thought out. Unusually, it had no crown on the side.

|

On arrival I was introduced to the young man responsible for the watch (and the photo shoot), Mr. Romain Gauthier and it was his name on the dial of the watch. Romain didn't look a day over 30 and I must admit to not having very high expectations when I asked to have a closer look at his watch(es).

What on earth was this calibre? Not only did it sport an easy to use winding system of a type I had not seen before, the layout of the beautifully finished movement was nothing like I had ever seen before. I asked Romain what his movement was based on. "I designed and made it myself" was his reply.

I went back to my open-jaw drooling with watch in one hand and loup in the other. It was some time before the photographer could prise the watch off me to commence shooting. (Did I really snarl?)

But the story really began over six years ago so let's go back to the beginning.

|

| The stunning Vallée de Joux |

Romain Gauthier was born in 1975 in Le Sentier, la Vallée de Joux: the very heart of traditional Swiss watch making. After studying precision-mechanics he went on to gain a diploma as a constructor of precision machinery. In 1997, Romain started his first job as a CNC machine programmer/operator at very highly regarding horological parts manufacturer in la Vallée de Joux.

Itis no exaggeration to say that over the following years he managed and grew the small CNC machine department into what has become one of the - if not, the - most well equipped and efficient production facilities in Europe.

But Romain had an itch.

He both loved horology and felt an entrepreneur inside himself desperate to get out. Surely he could marry the two." In 1999, Romain started thinking about what he could do on his own in the world of watches and in 2000, " My first idea was to set up as a consultant to collectors advising them on the quality of movements and watches. From there I became more ambitious and thought to start my own watch brand, i.e., design my own watch but using third party movements."

|

Romain was 25 years old.

Appreciating that in order to realise his dream needed more business/commercial skills, Romain decide to get them so enrolled in an MBA; and in doing so became the youngest person at the Business School to do so.

"A few months after starting the MBA, and still thinking to work in some type of capacity as an horological consultant, I went to talk to Philippe Dufour in relation to a MBA project I was studying. After talking to him and seeing how he worked I was inspired to design and make my own watch - including the movement. I asked Philippe if it was possible to design a movement and he replied, 'Sure, no problem.' So I set to work."

Completing his MBA in 2002, Romain's final thesis - passing with distinction- was the business plan for Montres Romain Gauthier. Now he started work on the watches. " I knew that a good movement was the basis of everything I planned to build, so I started with that."

And the design of the movement?

"The off-centered dial was inspired by Lange & Sohne's Lange 1 as I thought it a very nicely balanced design."

Regarding the winding mechanism: from an engineering/mechanical point of view, distributing power from the crown via a long thin winding stem then turning it through 90° to the mainspring barrel appeared to be an overly complicated approach. Ubiquitous perhaps and well refined over the years; however, Romain was starting from a clean sheet of paper.

"I had the idea to put the crown under the watch and asked Philippe (Dufour) if there was any reason why I couldn't/shouldn't. He told me that both Jaeger leCoultre and Audemars Piguet had done something similar in the past and that he could not think of any reason against it. "

" Their watches however could only be wound up while off the wrist and I wanted a crown that could be easily wound while the watch was being worn. That requirement plus the off-centered dial were my starting points for the movement design. I then decided on the escapement at six o'clock and a symmetry - wheels and bridges - between the balance wheel and the second wheel."

|

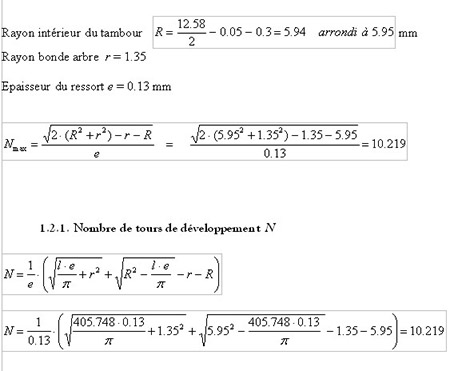

| This is just part of the formula to work out number of turns in a spring. |

The following year (2003), Romain went back to Phillipe Dufour with the

draft plans for his movement. Phillipe liked the fact that I used traditional

Vallée de Joux style 'finger' bridges and made some suggestions which

I took into account.

"Now all that was left was working out all the mathematics of the gear ratios and teeth etc. That took some time."

While Romain knew how to design machines, and watch movements are simply machines on a small scale, the minuscule scale of the components meant that he had to do quite a lot of study to ensure that what looked fine in theory would work well in practice.

From very early one there were parts that were fixed in size and shape.

Romain started making those even while he was working out the intricate

shapes of others.

Manufacture

|

Perhaps the biggest obstacle facing any independent watchmaker wishing to make a movement is actually getting high-quality parts made. Even with the skills to use CNC machines - which the majority of watchmakers do not - they cost hundreds of thousands of dollars: a sum way beyond the reach of the majority.

When you order parts from a specialist manufacture, much of the time and expense is in the programming and setting up of the machines so it is not economical to make just a few parts for a few movements. Ideally you need to make a few hundred parts for a few hundred movements and that would cost a small fortune! This is a major factor in the price of watches produced in small quantities.

|

| Romain at the controls of one of the most sophisticated CNC machines in Europe. |

Romain however had a very good friend time who

admired his passion and determination. Romain's friend was able to give him after-hours and weekend access to some very sophisticated CNC machinery.

Romain spent the last three years working late, weekends and on his holidays making all of the parts for his first series of timepieces. Even with help that is an incredible achievement.

And one other thing: Romain worked for those three years in near total

secrecy. "I wanted to take my time, to learn and to do things properly

without the pressure of others asking questions, so whenever I had to involve

a third part to supply parts I used a fictitious company name."

|

| Watchmaker Sébastien Berney |

August 2006 and Romain had finished making all of the parts, now it was a question of putting them together. While he had the skill to design the movement and to make the component parts, Romain knew that he needed a trained watchmaker to apply the fine finishing, assemble and regulate his watches. Long standing friend and talented young watchmaker, Sébastien Berney, joined Romain and set to work on the first prototypes.

Trial by Fire

"When we finished our first prototype we presented it to Philippe Dufour for his honest opinion. Philippe had heard nothing about what I was doing for the last three years so was surprised to say the least. He liked what we had done and also gave Sébastian a few tips and shared a few fine-finishing secrets."

Click to part 2: A closer look at Romain Gauthier's Collection Prestige

I welcome comments, suggestions, and corrections to this article.